Quality Assurance & Control Quality Assurance & Control

For a client to be confident that a product they are purchasing or using (e.g. a valve, pipe, vessel etc.) meets not only their original expectations, but also any legislative obligations, an effective quality assurance and control program should be implemented that can monitor the quality of the product throughout it lifetime.

Inspecta International offers a comprehensive range of QA / QC services to provide our clients with that piece of mind and confidence that a product meets and in most cases exceeds their requirements, whilst performing as per the manufacturers specifications, and conforming to the statutory laws and guidelines.

We possess a highly qualified & certified team of QA/QC specialists (Civil, Coating, Mechanical, E & I) who are seconded to manufacturers and suppliers worldwide.

- General QA / QC Services

Inspecta International is able to establish QA Plans and Procedures that set the performance standards; methods for measuring, evaluating, auditing & reporting performance; as well as procedures for handling situations when performance deviates from the standard.

- Third Party Vendor Inspection

Inspecta International provides an extensive range of third party vendor inspection related services to engineering & procurement clients on a global basis - supplier assessments, inspection, expediting, outsourcing, destructive & non-destructive testing and coordination. This helps clients to reduce costs, whilst adhering to technical & commercial requirements. Furthermore the service controls the quality of workmanship from manufacturer as well as ensuring conformity to purchase specifications.

- Total Quality Management (TQM)

Inspecta International is able to offer a comprehensive TQM package to ensure quality is controlled through the life of a project, from raw material, through milling, shop fabrication, site construction to start up and commissioning.

Should you require further information regarding our QA services, please contact Inspecta International by emailing enquiry@inspectagroup.org.

Plant Integrity Plant Integrity

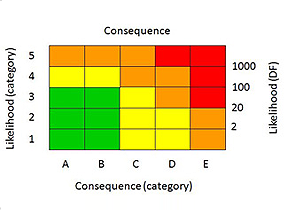

Risk Based Inspection (RBI)

Within any operational setting, not all components or parts have an equal likelihood of failure, nor are the consequences the same should failure occur. In order to save time and money, whilst still maintaining optimal levels of safety, it is extremely useful for an operator to know which locations within a system are of greater concern than others.

Inspecta International is able to undertake a Risk Based Inspection (RBI) that takes into account both likelihood of failure and consequences of failure, to allow clients to make more informed decisions regarding inspection schedules and maintenance budgeting, allowing resources to be allocated appropriately to ensure reliability and integrity.

An effective RBI program will highlight those high-risk areas that should come high in the maintenance schedule, whilst identifying those of low risk that can be placed further down the schedule.

Our RBI Inspectors review all relevant data pertaining to the system including maintenance history and industry guidelines as part of a comprehensive risk assessment and assign ratings to all parts of the system, from which the client can then prioritise inspection and maintenance programs.

Fitness For Service (FFS) & Remnant Life Assessment (RLA) Fitness For Service (FFS) & Remnant Life Assessment (RLA)

No matter how well a component or part has been manufactured, overtime it will naturally degrade and eventually fail. Most products of this nature come with a minimum safe operating life span stated by the manufacturer, but this can and will change depending primarily on operating conditions (temperatures, chemicals, environment, loads etc.).

In order to achieve the maximum life out of a component, without compromising safety or reliability, operators need to have a clear understanding of residual life.

Inspecta International is able to undertake a complete assessment of a system to evaluate how long individual components can safely remain in situ, making the decision process to "run", "replace" or "repair" easier for operators.

RLA, when correctly applied, not only provides an accurate assessment of residual life (based on existing and future operating conditions), but also allows for more effective maintenance planning so resources are not wasted and time and money can be allocated to those components as necessary.

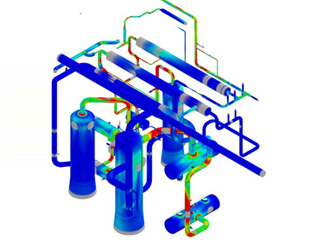

To carry out an RLA, Inspecta International gathers data from a number of sources; manufacturers design specifications, operating statistics, maintenance history, NDT. Computer modeling then allows us to accurately predict residual life and identify those components that need immediate attention.

Using Integri-Tech FFS technology, Inspecta International offers the most powerful approach to FFS and can provide all levels of assessment, from a one-off program to periodic monitoring, all in accordance with applicable Codes. All defect mechanisms can be included, along with any combination of loadings (not just pressure) to determine an accurate Integrity status. For example corrosion, vibration and FPSO motion plus process cycles of pressure & temperature can be included in a single assessment.

Using this technology,we are able to offer the only continuous Remote FFS monitoring technology in the world, integrity assessments are available in real time and inspectors are able to quantify integrity and accurately predict remaining life.

Furthermore FFS can be used to evaluate and re-rate pressure vessels, piping and storage tanks.

Should you require further information regarding our Plant Integrity services, please contact Inspecta International by emailing enquiry@inspectagroup.org.

Conventional Non Destructive Testing (NDT) Conventional Non Destructive Testing (NDT)

Inspection and testing of a material or components whilst in situ, without interruption to processes, and without destroying it is an extremely useful tool to determine integrity.

Inspecta International, operating the latest technologies, offers a complete conventional NDT service, - Visual Testing, Radiography, Ultrasonics, Penetrant and Magnetic Particle.

NDT is used for:

- Flaw Detection and Evaluation

- Leak Detection

- Dimensional Measurements

- Structure and Microstructure Characterization

- Estimation of Mechanical and Physical Properties

- Stress (Strain) and Dynamic Response Measurements

- Material Sorting and Chemical Composition Determination

|

Our NDT department, consisting of engineers, technicians, inspectors and consultants, are committed to providing our clients with cost saving solutions that will ensure safety and reliability during operations.

NDT is a proactive, preventative inspection approach that has a number of benefits:

- Performed without disruption to the system or production,

- Relatively fast to set up and to carry out,

- Provides detailed information regarding integrity in accordance with standards and legislative requirements,

- Cost saving and safety assurance,

- Can be deployed at any stage of an asset's lifecycle, from procurement to operations.

Equipment currently in use:

- Krautkramer USM 35X, USM 35, USM 25, USN 52, DMS 2, DMS 4.

- NDSTechOps 660 & Delta 880,Sentinel 660.

- Magnaflux – PT, MT Consumables.

- Baltospot Portable Xray

- IplexBoroscope, FLIRThermocam Digital Imaging E450.

- TWI GAL Gauge.

Should you require further information regarding our NDT services, please contact Inspecta International by emailing enquiry@inspectagroup.org.

Advanced Non Destructive Testing (NDT) Advanced Non Destructive Testing (NDT)

Inspection and testing of a material or components whilst in situ, without interruption to processes, and without destroying it is an extremely useful tool to determine integrity. As manufacturing has become more complex and the need for more detailed integrity assessment increased, inspection technologies have had to keep up to provide effective inspection solutions.

Inspecta International is able to offer a full range of advanced NDT techniques, to provide our clients with the most suitable solution to their inspection requirements. Technological developments in recent years have led to an array of innovative techniques that allow inspection of material and structures at an advanced level, including:

- Automated NDT

- Time of Flight Diffraction

- Ultrasonic Phased Array

- Long Range Ultrasonics

- Internal Rotary Inspection System

- Remote Field / Pulsed Eddy Current

- Magnetic Flux Leakage

- Alternating Current Field Measurement

- Digital / computed Radiography

- Small Controlled Area Radiography

- Insulated Component Test

- Real Time Radiography

- Gamma Scanning

- Large Structure Inspection System

(See our Technical Pages for further information and to download an info sheet)

Equipment currently in use:

- Ultratech MT Scanner,

- Olympus Omniscan MX,

- GWU Wave Maker G3,

- Olympus RD Tech TC5700, MS5800,

- Silverwing Floormap VS2,

- Lixi Radiometric Profiler,

- SentinalQSA Global 959M,

- Amigo ACFM System U31D,

- PAL Spartan AT SN 157,

- Silverwing MFL2000,

- Harfang X32 PA,

- ANDSCAN,

- ZetecMIZ 21 SR, 27 ET,

- Olympus Omniscan MX2,

- Olympus Multiscan MS5800.

Should you require further information regarding our advanced NDT services, please contact Inspecta International by emailing enquiry@inspectagroup.org.

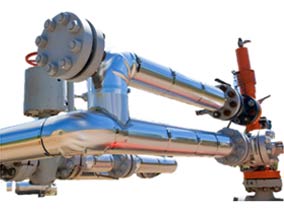

Pipeline Integrity Assessment

Pipeline owners and operators are often faced with a number of challenges when it comes to assessing integrity, which are often centered around access, particularly when the pipework is buried or sub sea. In addition, welds create potential areas of weakness that require inspection to confirm integrity. Pipeline Integrity Assessment

Pipeline owners and operators are often faced with a number of challenges when it comes to assessing integrity, which are often centered around access, particularly when the pipework is buried or sub sea. In addition, welds create potential areas of weakness that require inspection to confirm integrity.

Inspecta International offers its clients a number of services designed to assess the integrity (internal and external) of pipework, which takes the uncertainty out of knowing its condition. Client corrosion monitoring programs may consist of one or more of the following;

- Cathodic Protection (CP)

CP is widely used for controlling corrosion of metallic pipework or structures that are in contact with electrolytically conducting substrates such as soil and water, by reducing the metal's corrosion potential and thus its corrosion rate.

- Direct Current Voltage Gradient (DCVG)

DCVG uses voltage gradients within the substrate surrounding a buried pipeline to assess its coating, allowing defects to be located and sized. To be effective the pipe has to be protected by an impressed current cathodic protection system, although a temporary equivalent can be installed for the purposes of the inspection.

- Close Interval Potential Survey (CIPS)

Typically a buried pipeline is protected from corrosion by a cathodic protection system and a set of test stations that monitor its effectiveness. However many systems are not able to assess the entire length of pipe and as such only measure protection in a localised area. CIPS is designed to assess protection along the entire length of pipeline, by measuring the pipe / soil potential using a fixed trailing wire connected to the pipe and a set of reference electrodes located along the inspection length (typically every metre).

- Intelligent Pigging

An intelligent pig is a device, containing one or more measuring instruments, that is placed inside a pipeline to collect data along its length in an attempt to assess the integrity of the pipe. Once analysed, the information can be used to pinpoint areas of concern and help coordinate maintenance resources appropriately.

- Welding Inspection

Various NDT techniques can be used to assess the integrity of pipeline welds, be it during its construction or an in-service inspection. In addition to conventional methods, more advanced techniques can be more cost effective, including phased array, time of flight diffraction.

Equipment currently in use:

- CathTechHexcorderMillenium,

- Olympus Omniscan MX,

- NDSTechOps 660, 880.

Should you require further information regarding our pipeline integrity services, please contact Inspecta International by emailing enquiry@inspectagroup.org.

Well Integrity Services

Effective management of well integrity helps operators keep maintenance costs down, whilst ensuring the safety and productivity of the well. Well Integrity Services

Effective management of well integrity helps operators keep maintenance costs down, whilst ensuring the safety and productivity of the well.

Inspecta International provides it clients with a complete well integrity package to ensure early detection of potential issues.

Our services include:

- Well & Production Testing

- Wireline & Completion Services

- Coiled Tubing, Nitrogen & Pumping Services

- Cementing & Stimulation Services

- Casing Inspection

Should you require further information regarding our Well Integrity services, please contact Inspecta International by emailing enquiry@inspectagroup.org.

Tubular Inspection Tubular Inspection

Effective maintenance of drill pipe and associated hardware ensures the continued and safe operation of a drilling rig.

An appropriate tubular inspection program helps identify integrity issues before they reach criticality, preventing costly repairs and / or damage to personnel and the environment.

NDT/Tubular Inspection and Management Service

Inspecta International Group offers quality NDT/Tubular Inspection and Management services in which we inspect and manage large quantities of tubular, bottom hole assemblies, valve parts and other drilling equipments.

Our NDT/Tubular Inspection Management service includes:

- • Tubular Inspection Services

• Tubular Non-Destructive Testing and Coating Services

• Tubular Running and Management Services

All inspections are carried out in accordance with client requirements and per the specified standard (API, DS1 etc).

Should you require further information regarding our Tubular Inspection services, please contact Inspecta International by emailing enquiry@inspectagroup.org.

Rig Surveys Rig Surveys

Throughout the operating life of a drilling rig, components can fatigue and systems fail, leading to dangerous conditions for personnel and the environment.

Inspecta International is able to offer a comprehensive rig survey (onshore or offshore) to provide clients the reassurance of a fully functioning and safe drilling rig. Our rig inspection services cover all stages of a rig's life, from construction thought to commissioning and operations.

The exact scope of our rig surveys is dependent on client specifications, however a typical survey package may include:

- Derrick Inspection (API 4F)

- Dropped Object Survey,

- Special Periodic Survey (ABS)

- Hull Thickness Survey (ABS)

- Lifting Equipment Survey (LOLER)

- Alignment Survey

- Safety & Emergency Systems Assessment

- Control Systems Assessment

Throughout the process, our inspectors review and ensure conformity to relevant codes, manufacturer's recommendations and legislation.

Our final reports provides a detailed breakdown of a rig's condition, which includes highlighting high-risk areas of concern where immediate maintenance is required.

Should you require further information regarding our rig survey services, please contact Inspecta International by emailing enquiry@inspectagroup.org.

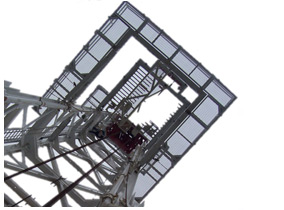

Rope Access Inspection Rope Access Inspection

Due to the complex design of plants and inaccessible nature of offshore rigs and platforms, inspections are often required in areas where access is limited or non-existent without costly scaffolding or cranes.

Inspecta International has a team of IRATA qualified and experienced rope access technicians who, using techniques developed for climbing and caving, are able to carry out inspections safely at height or in difficult to access locations.

As part of our service, we provide a detailed risk assessment and method statement for each job, allowing us to carry out the work safely, quickly and effectively, minimizing client's project costs.

Using rope access has a number of benefits over scaffolding or cranes, including:

- Rope access is adaptable to almost any situation onshore and offshore,

- Rope access is relatively fast to set up and dismantle, thus increasing the inspection time window,

- When compared to scaffolding, rope access can offer significant savings to clients,

- Using technicians trained in both inspection and rope access provided clients with a single point of contact,

Inspecta International provides continual training to our rope access personnel, in line with IRATA guidelines.

Should you require further information regarding our rope access inspection services, please contact Inspecta International by emailing enquiry@inspectagroup.org.

Subsea Integrity Services

Subsea Integrity Services

Offshore pipelines and structure operate in extreme environmental conditions that can lead to mechanical failure if not adequately maintained.

Inspecta International provides clients with a number of sub sea inspection services appropriate for offshore activities including:

- Close visual inspection,

- Video & photographic surveys,

- Ultrasonic wall thickness measurements,

- Ultrasonic flaw detection,

- Alternating Current Field Measurement (ACFM)

- Flooded Member Detection System

- Magnetic particle testing

- Eddy current Testing,

- CP survey,

- Maintenance & repair

- Hull cleaning

- Welding – anode replacement, hull, braces and column repairs,

- Air diving,

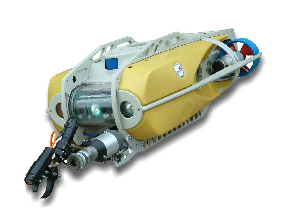

- Remotely Operated Vehicle (ROV) Survey.

We own and operate diving equipment and specialized NDT inspection technologies, all of which conform to IMCA guidelines.

Our ROV survey teams, deploying our NAVAJO ROV or See Eye Falcon ROV, are able to carry out inspection in coastal waters as well as deep sea (up to 300 metres).

Equipment currently in use:

- NAVAJO ROV,

- Sea Eye Falcon ROV,

- ASAMS MPI System,

- RSL Flaw Detector,

- Cygnus 1 Thickness Gauge,

- Buckleys Bathy Corometer,

- AmphibicoHandycam,

- ACFM U31D,

- 60" Twin Lock DDC,

- 10' Machinery Container (inc 2x20 CFM HP Compressors),

- IMCA Compliant Launch and Recovery System,

- Kongsberg Video System,

- Amron / Hytech Communicators,

- KMBBandMask 18, KMB Helmet 37,

Should you require further information regarding our subsea inspection services, please contact Inspecta International by emailing enquiry@inspectagroup.org.

Lifting Equipment Inspection Lifting Equipment Inspection

Lifting equipment is subject to high static loading and an unpredictable set of dynamic conditions that can lead to mechanical failure. Periodic inspection is therefore necessary to optimise safety and ensure the equipment is working correctly and efficiently.

Inspecta International offers inspection services for the full range of lifting equipment including cranes, goods lifts, platforms, slings etc, and in line with the Lifting Operations & Lifting Equipment Regulations (LOLER) framework, our inspectors are able to carry out inspections to determine that:

- The equipment is installed correctly and safe to operate,

- The equipment is a good state of repair,

- Any deterioration is identified and rectified in a timely manner.

As part of our inspection service, we undertake:

- ITP review,

- Visual & dimensional checks,

- Roof clearance test,

- Pendent length check,

- Stability test,

- Insulation test,

- Light run test,

- SWL test,

- Overload test,

Should you require further information regarding our lifting equipment inspection services, please contact Inspecta International by emailing enquiry@inspectagroup.org.

Specialized Training For The Petroleum Industry Specialized Training For The Petroleum Industry

The technology, legislation and guidelines relating to NDT and Asset Integrity Inspection is ever-changing and as a result, continual training and development is crucial to all personnel to maintain up to date skills and knowledge.

Inspecta International provides training in the following areas:

NDT Inspection

- American Society for Non-destructive Testing (ASNT) - Levels I, II & III

- Personnel Certification Notification (PCN) - Levels I, II, & III

- Certification Scheme for Welding Inspection Personnel (CSWIP)

CSWIP 3.1 – Welding Inspector

CSWIP 3.2 – Senior Welding Inspector

Welding Inspection

- American Welding Society (AWS)

CAWI – Certified Associate Welding Inspector

CWI – Certified Welding Inspector

SCWI – Senior Certified Welding Inspector

Plant Inspection

- American Petroleum Institute (API)

API 570 – Pressure Piping Inspector

API 510 – Pressure Vessel Inspector

API 563 – Storage Tank Inspector

API 579 – Fitness For Service

API 580 – Risk Based Inspection

Painting Inspection

- British Gas Approval Scheme (BGAS)

Grades I, II & III

- National Association of Corrosion Engineers (NACE)

CIP Levels I, II & III

Subsea Inspection

- International Marine Contractors Association (IMCA)

Lifting Equipment Inspection

- Lifting Equipment Engineers Association (LEEA)

Rope Access Inspection

- Industrial Rope Access Trade Association (IRATA)

In addition, Inspecta International, through its subsidiary company the Petroleum Training Institute (PTI), provides training across all areas of petroleum production and processing (upstream, midstream & downstream). In addition, Inspecta International, through its subsidiary company the Petroleum Training Institute (PTI), provides training across all areas of petroleum production and processing (upstream, midstream & downstream).

The PTI in collaboration with its partner company TRONiX aims to offers students an unparalleled training experience through the use of virtual reality labs, classroom based teaching, simulation training and state of the art applied technologies.

For further information on the Institute, refer to the website www.petrotrain.org or download a brochure here

Should you require further information regarding our any of our Specialised Training services, please contact Inspecta International by emailing enquiry@inspectagroup.org, or contact your local office who will be happy to answer any queries www.inspectagroup.org.

|

|